The Key to Breakthrough in Sports Bra Manufacturing: Embracing Smart, Digital Production

A Booming Market with Hidden Challenges

As public health awareness continues to grow, sports and fitness have become part of daily life. Sports bras are essential for comfort and safety during exercise. As a result, demand in the market is rapidly increasing.

However, behind this booming trend, manufacturers face serious production challenges. These issues affect both efficiency and product quality.

Pain Points in Traditional Sports Bra Manufacturing

1. Challenges in Conventional Cutting Processes

Low Dimensional Accuracy

Manual fabric laying and cutting often lead to size deviations. This impacts the fit and support of the final product.

High Material Waste

Pattern nesting is done manually. This results in poor fabric usage and a large amount of corner waste. Material costs rise as a result.

Low Cutting Efficiency

The process relies heavily on manual labor. Multiple steps are time-consuming. This leads to longer production cycles and delays in delivery.

2. Challenges in Traditional Gluing Techniques

Inconsistent Glue Application

Manual or semi-automatic gluing cannot accurately control glue dot size, thickness, or spacing. This affects adhesion strength and product appearance.

Positioning Errors

Glue dot placement depends on manual alignment. This makes it easy to misplace glue, resulting in weak bonding or visual defects.

Low Production Throughput

Manual or semi-automated processes are slow. It becomes difficult to meet high-volume production needs.

Difficult Control of Glue Layer Thickness

Too much glue reduces breathability and softness. Too little glue leads to poor bonding. Finding the right balance is hard to achieve manually.

GBOS Smart Solutions: Elevating Production from Precision Cutting to Seamless Gluing

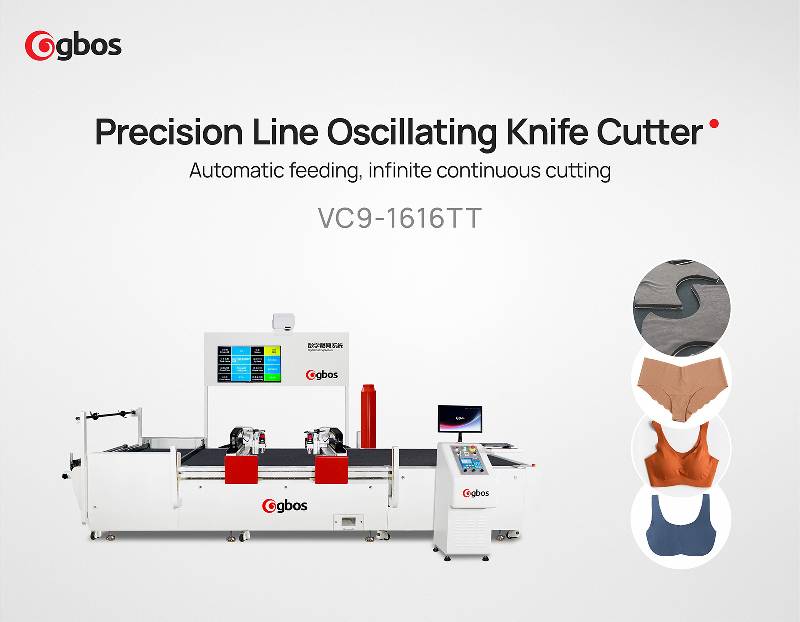

To solve these challenges, GBOS offers a digital, intelligent production solution. It includes the VC9-1616TT Intellgent Oscillating Knife Cutting Machine and the DP-GN1280TT-AT-SCCD PUR Seamless Gluing System.

VC9-1616TT Oscillating Knife Cutting Machine can do the following:

Precision Cutting

Digital control ensures high cutting accuracy. This improves product fit and support.

Maximized Fabric Utilization

An intelligent nesting algorithm optimizes fabric layout. It reduces waste and saves material.

Faster Production Speed

The fully automated process shortens production time. Output capacity increases significantly.

Key Features of VC9-1616TT:

Dual-head Asynchronous Cutting System

Two cutting heads work simultaneously. Cutting efficiency is doubled.

Multi-layer Automatic Clamping & Feeding System

This system ensures smooth, accurate feeding. Materials remain flat and undamaged.

One-piece Machine Casting

The machine body uses a one-piece casting design. This prevents deformation under heavy load and extends the equipment’s lifespan.

Projection Preview Positioning System

Operators can preview the layout in real time. This makes the operation more intuitive and precise.

IoT Bridge (Internet of Things)

The system connects all machine data in the smart workshop. It helps eliminate data silos and improves equipment performance management.

DP-GN1280TT-AT-SCCD PUR Seamless Gluing System can do the following:

Consistent Glue Dot Control

Glue dot size and thickness are digitally controlled. This ensures strong bonding, breathability, and softness.

High-Precision Positioning

The system combines digital design with automatic application. Glue dots are accurately placed for consistent results.

Enhanced Production Efficiency

The gluing system works seamlessly with the cutting machine. Together, they create a fast, high-output production line.

Reduced Material Waste

Glue quantity is precisely managed. This minimizes overuse and lowers environmental impact.

Key Features of DP-GN1280TT-AT-SCCD :

Dual-head Asynchronous PUR Gluing System

Two gluing heads operate independently. They provide over 98% accuracy. Spacing and size can be flexibly adjusted.

AI Vision Recognition System

The system automatically identifies cut piece shapes. It generates glue templates with one click. Manual positioning is no longer needed.

Simultaneous Multi-part Gluing

Multiple parts can be glued at the same time. This further boosts production speed.

Unlock the Future of Sports Bra Manufacturing

From smart cutting to seamless gluing, GBOS offers a complete digital solution. It helps manufacturers break through production limits and lead in a competitive market.

We invite you to explore this advanced system. Partner with GBOS to accelerate your production, improve quality, and build a smarter future in sportswear manufacturing.