/sites/default/files/styles/thumbnail/public/2023-04/H1%20%E4%B8%BB%E5%9B%BE.png?itok=dosDwgxM

HIGH PLY CUTTING MACHINE WITH DIGITAL

Model: H1

Specification Parameter

The right cutter for every segment

Perfection in all details

One-piece mold-opening crossbeam

The use of a one-piece mold-opening crossbeam in a high-layer knife cutting system has advantages such as a more stable structure, higher cutting accuracy, longer mechanical life, easier maintenance, and better stability. It can improve production efficiency and quality, and reduce manufacturing and maintenance costs.

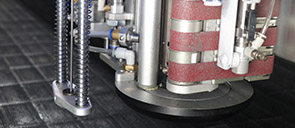

Sand belt grinding

The use of sand belt grinding results in a longer lifespan and faster sharpening of tools, significantly improving the efficiency of the grinding process and reducing production time and costs.

XY axis adopts precision gear and rack transmission

The XY axis of the precision gear and rack transmission adopts high-speed motion mode, ensuring high-speed cutting while also ensuring the stability and durability of the transmission system, improving production efficiency and effectiveness.

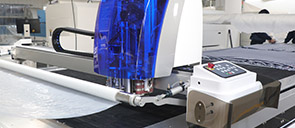

Automatic spreading machine

Traditional manual spreading may lead to human errors, while an automatic spreading machine utilizes precise mechanical operations and automatic controls, reducing human errors and improving production accuracy and consistency, while also reducing material waste.

The maximum oscillation frequency can reach 6000RPM

In the high layer blade cutting system, using high-frequency oscillation can improve cutting speed and quality, with strong adaptability, low noise, and low energy consumption advantages.

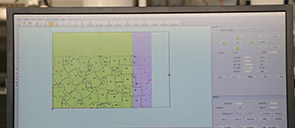

Autonomous software design

The self-designed software can be upgraded and updated according to the user's needs, and can quickly adapt to new processes and production requirements, improving the production capacity and efficiency of the equipment.

Multiple optional device are available

Including the blade cooling device, double punching device (single or double connection optional), lateral mobile device, in combination with multiple spreading machine tables, high suction bed device, anti-collision safety protection function, and other devices.

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts