GBOS cutting software designed to meet your requirements

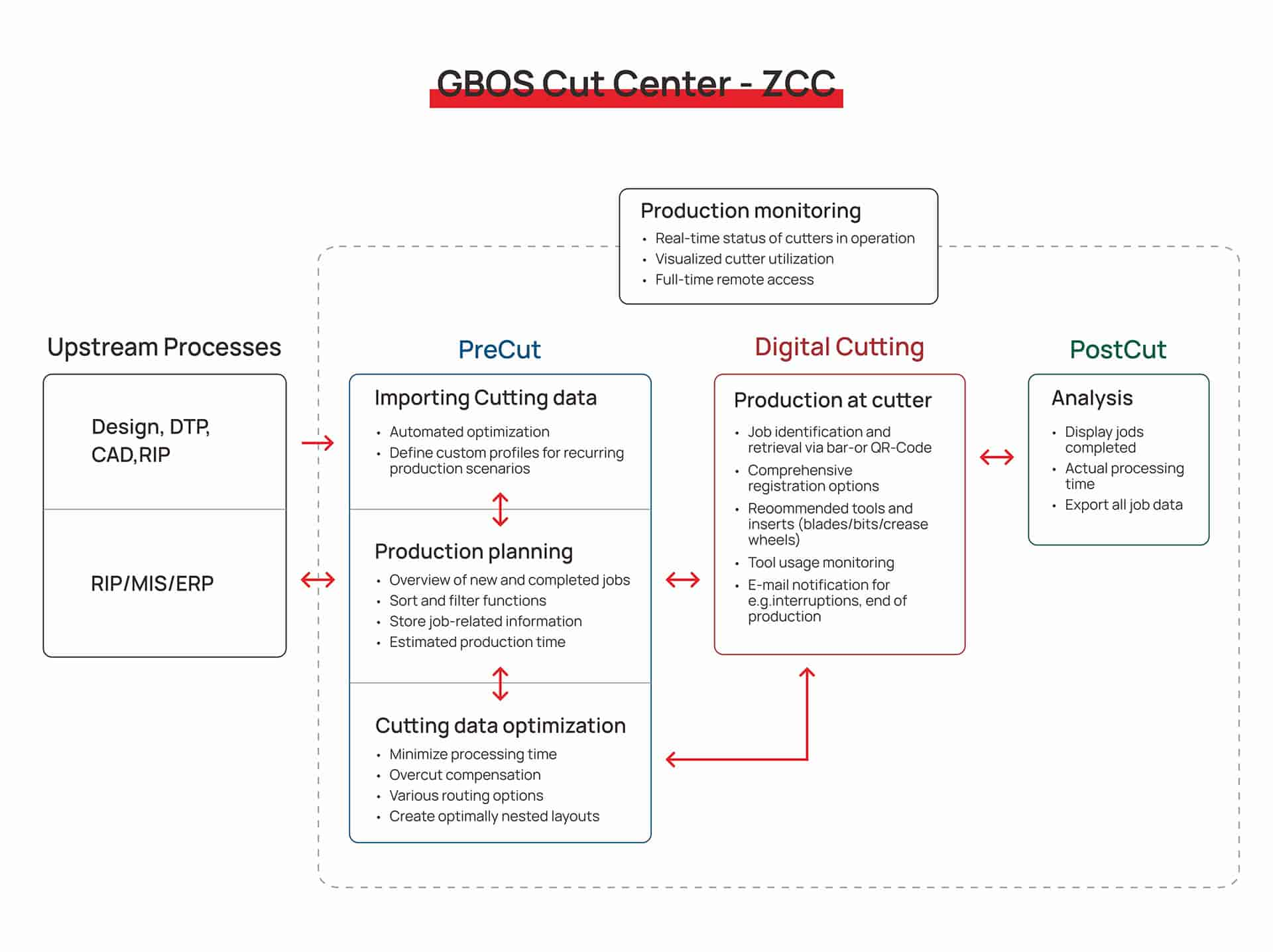

GBOS Cutting Center

Our cutting software are designed by GBOS R&D team with 3 years, to meet the needs of the current market and customers, provide customers with high quality brand services.

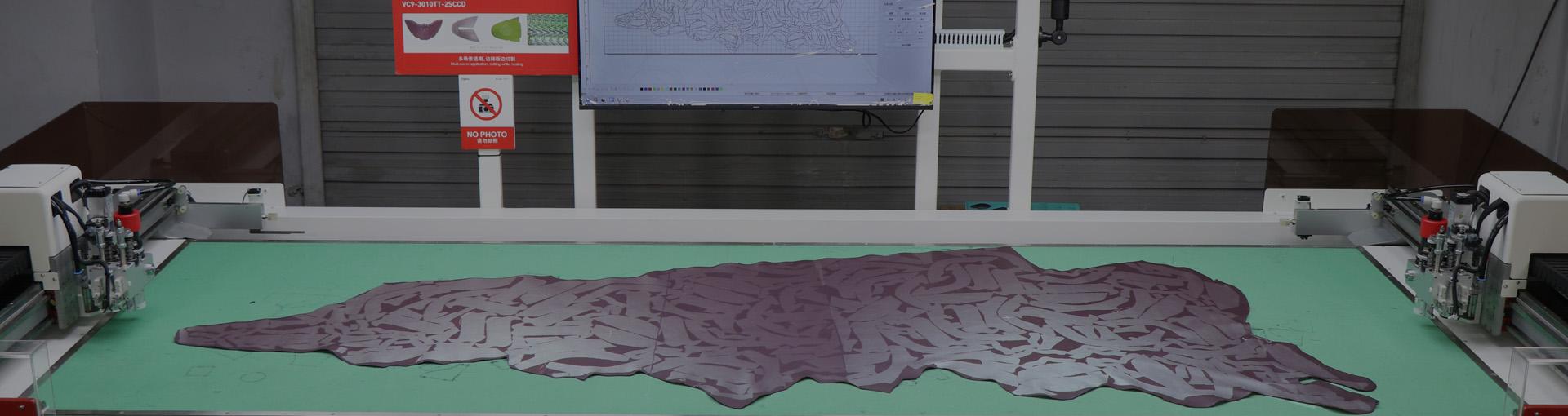

CUTTING SOFTWARE

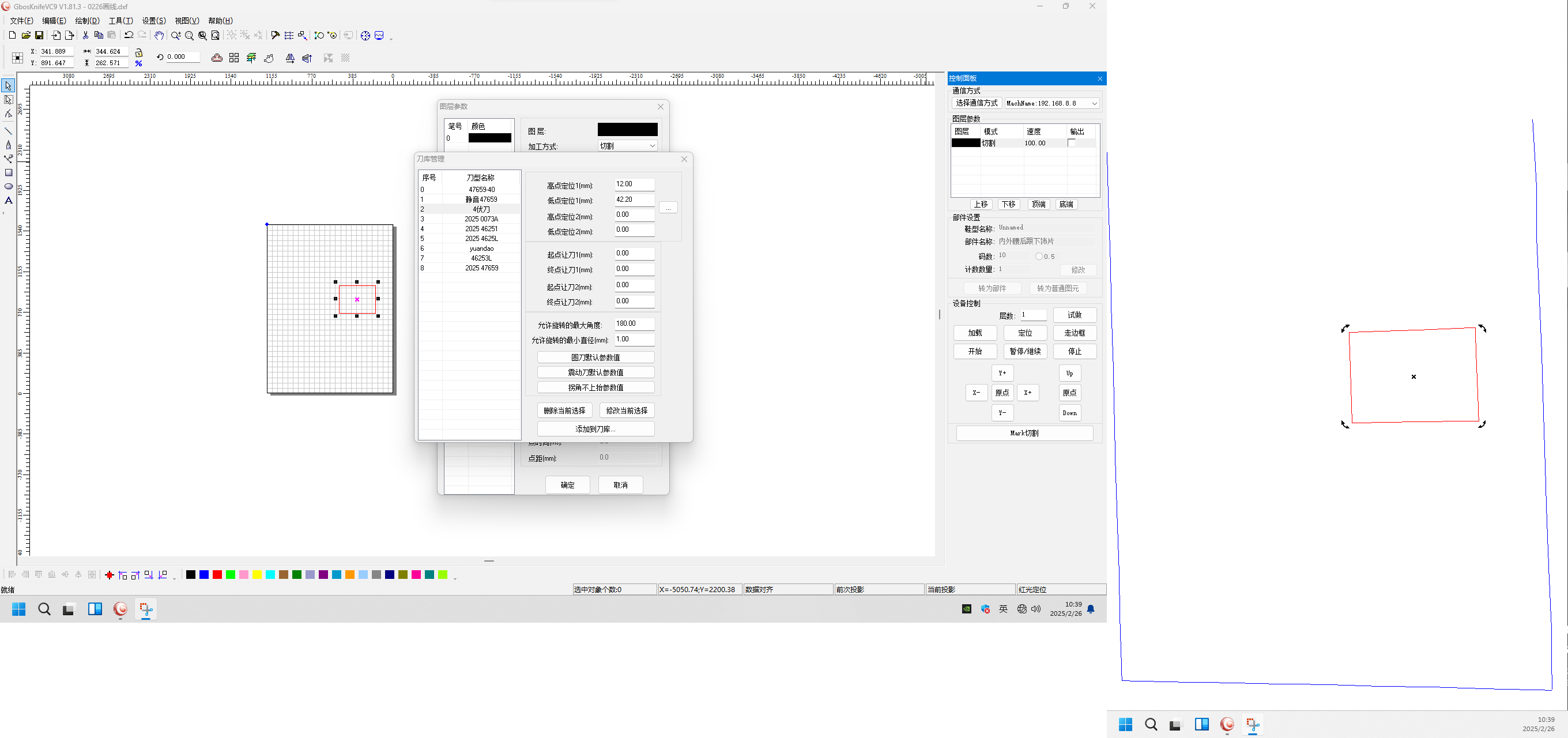

Depending on the requirements, different blades can be selected to achieve the desired process application.

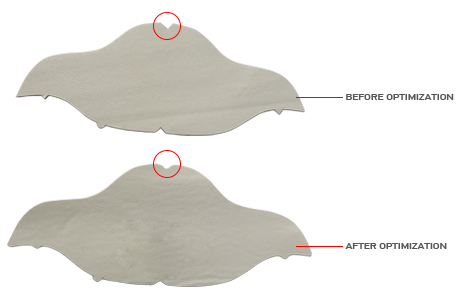

A, Increase speed B, Optimize cutting effect

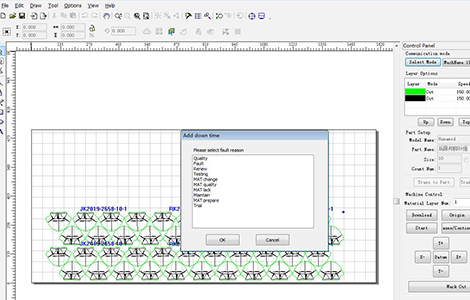

Projection preview positioning, real-time preview of nesting layout effects, convenient and fast.

Built in microcomputer control system.Even if the PC fails,it can ensure the normal operation of the machine

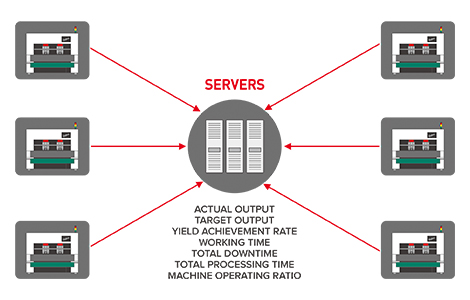

IoT Bridge

The operational status of the equipment can be viewed on the OEE Dashboard

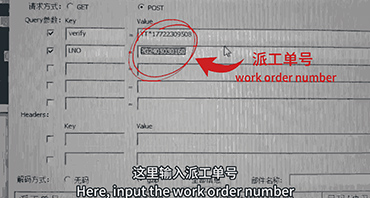

The IoT Bridge can communicate with the MES system

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts