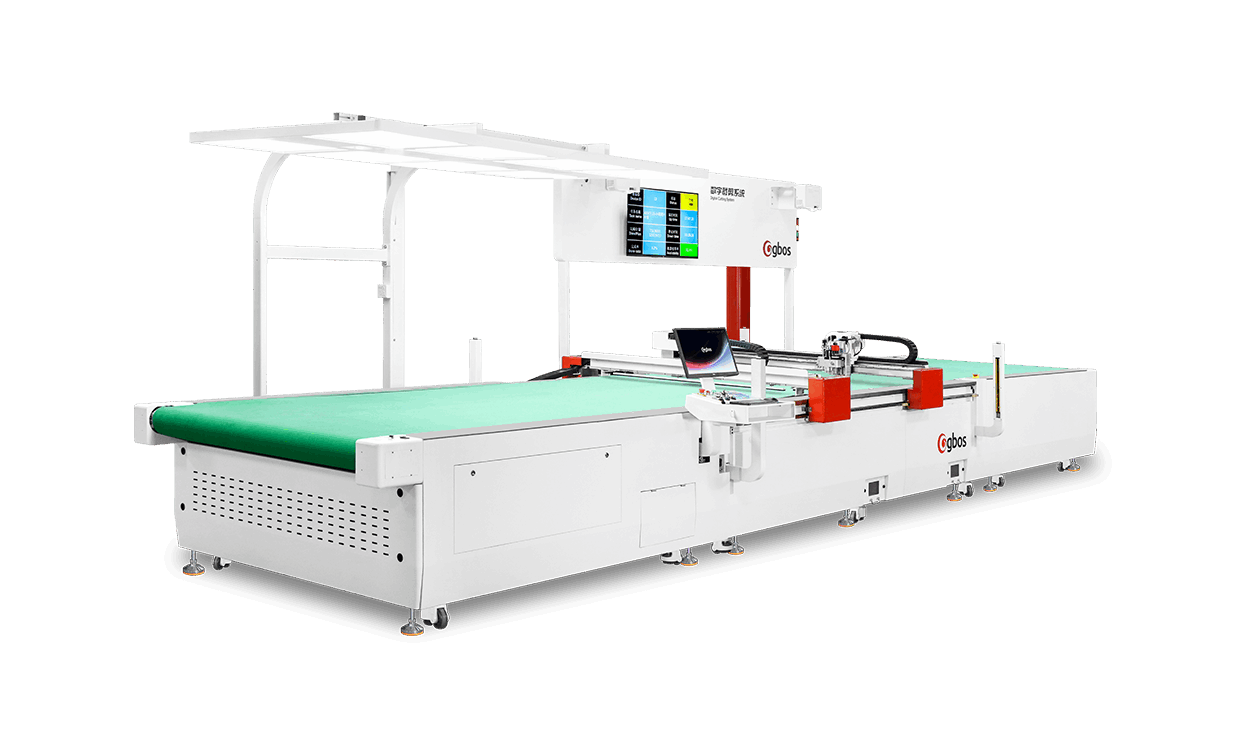

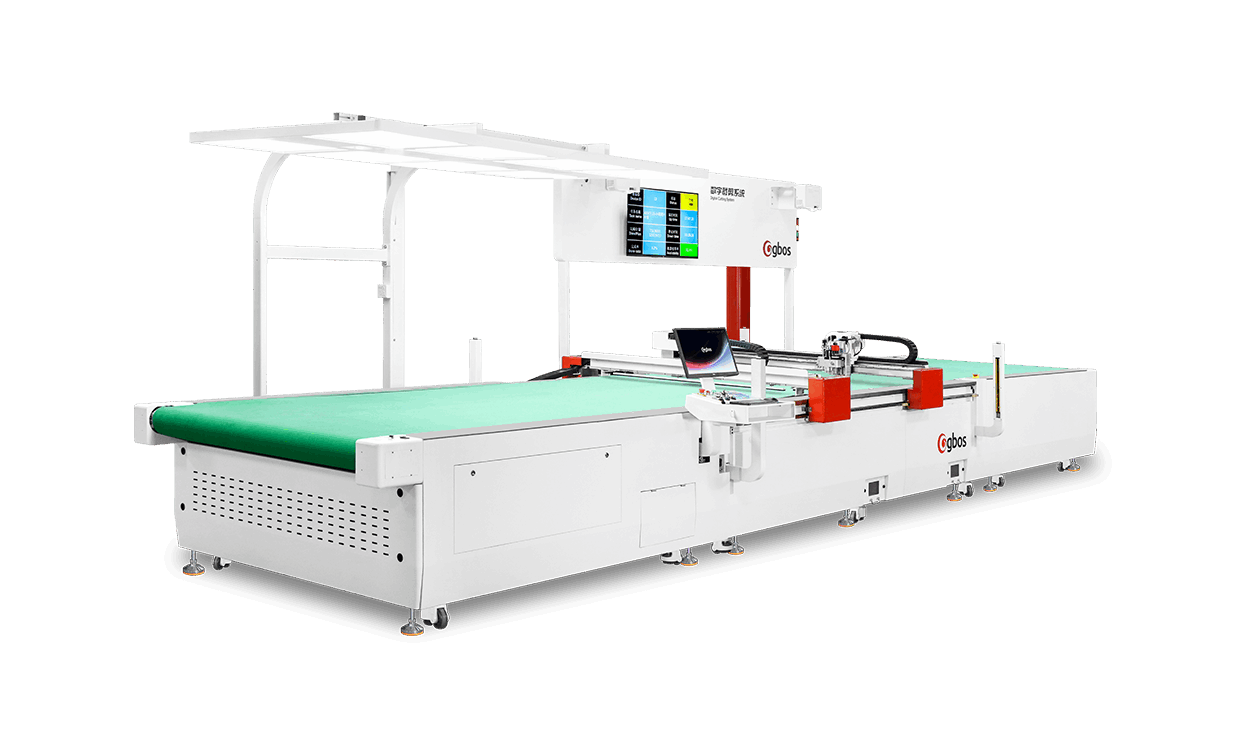

LEATHER SMART CUT FLOW LINE

Model:KC1625TT-RT-2P-ITS3-SP

Specification Parameter

The right cutter for every segment

Perfection in all details

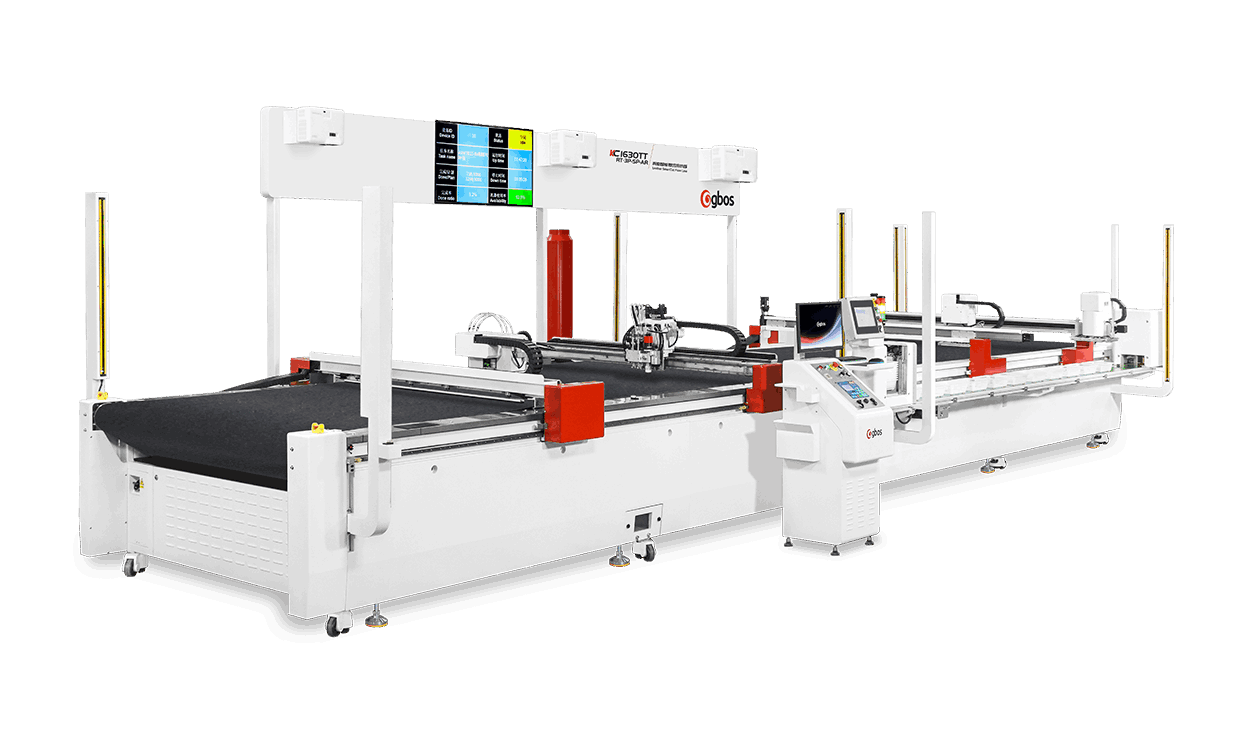

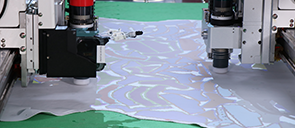

Double-head asynchronous cutting system

Dual-head asynchronous cutting system, with two knife heads that can work simultaneously to improve cutting efficiency.

Waste suction device

Waste suction device, featuring two punching units on each knife holder. After punching, the waste material is automatically sucked into the waste collection box, enhancing the cleanliness of the work area, achieving a cleanliness rate of over 90%.

Ink cartridge-based printing and coding device(optional)

Equipped with a cartridge-based marking device, which can automatically and quickly mark "flow numbers" on the leather before cutting, facilitating the next process after cutting. The marking device sprays lines that are even and clear, without breaks or ghosting. Suitable for fluorescent ink, permanent ink (water-based, neutral, UV).

Automatic pairing and material retrieval system (optional).

Save about ≈2 labor costs, Receiving way:Vacuum automatic sucking, manual checking.

Cutting line

Feeding way:automatic feeding, circulating conveyor belt; Receiving way:Vacuum automatic sucking, manual checking

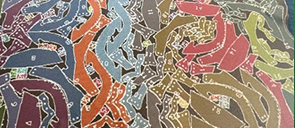

AI intelligent leather nesting system

Equipped with the latest GBOS AI large model, it automatically identifies leather defects, adapts to different colors and markings, greatly improving efficiency and saving manpower and time.

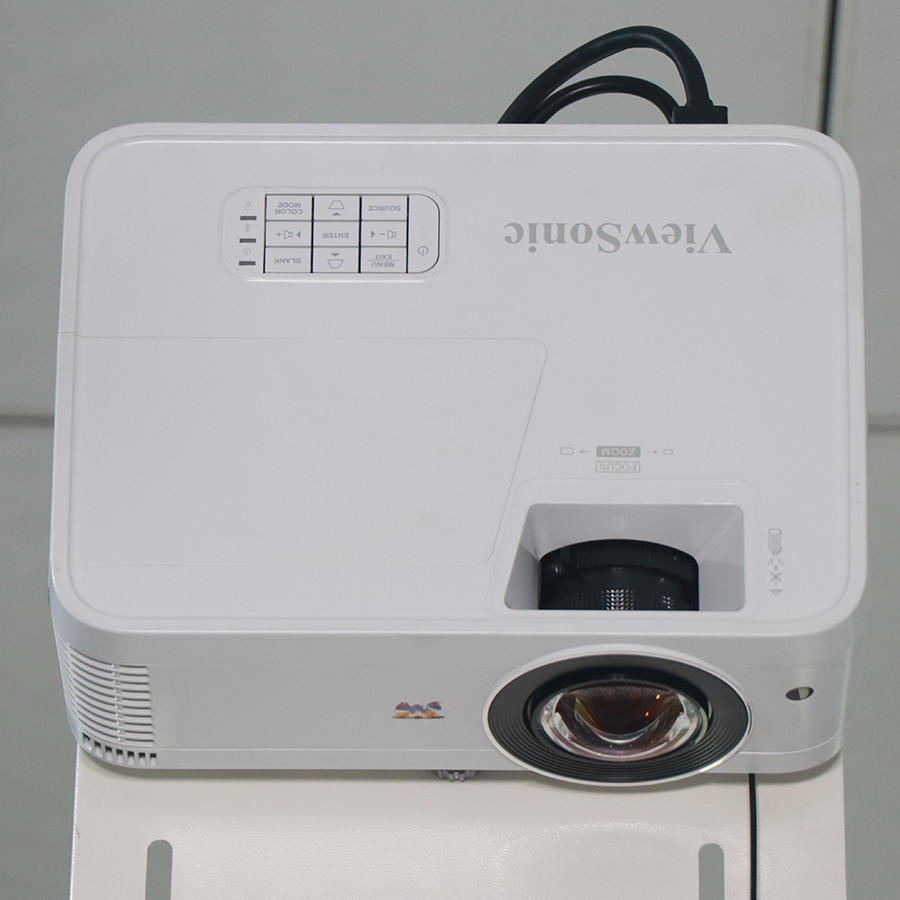

Projection preview function

Clearly project the nesting effect onto the material, allowing real-time viewing of the nesting effect and cutting status.

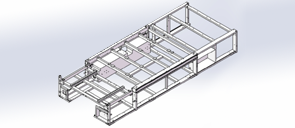

Integrated casting frame

Casting and natural weathering 24 months in advance, stable structure, high corrosion resistance, high precision cutting, lifespan of 20 years.

Partitioned vacuum system

Partitioned vacuum system is suitable for any kind of materials. It can effectively fix the material, ensure cutting quality. While also having energy saving design.

Modules & Tools

Material Application

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts