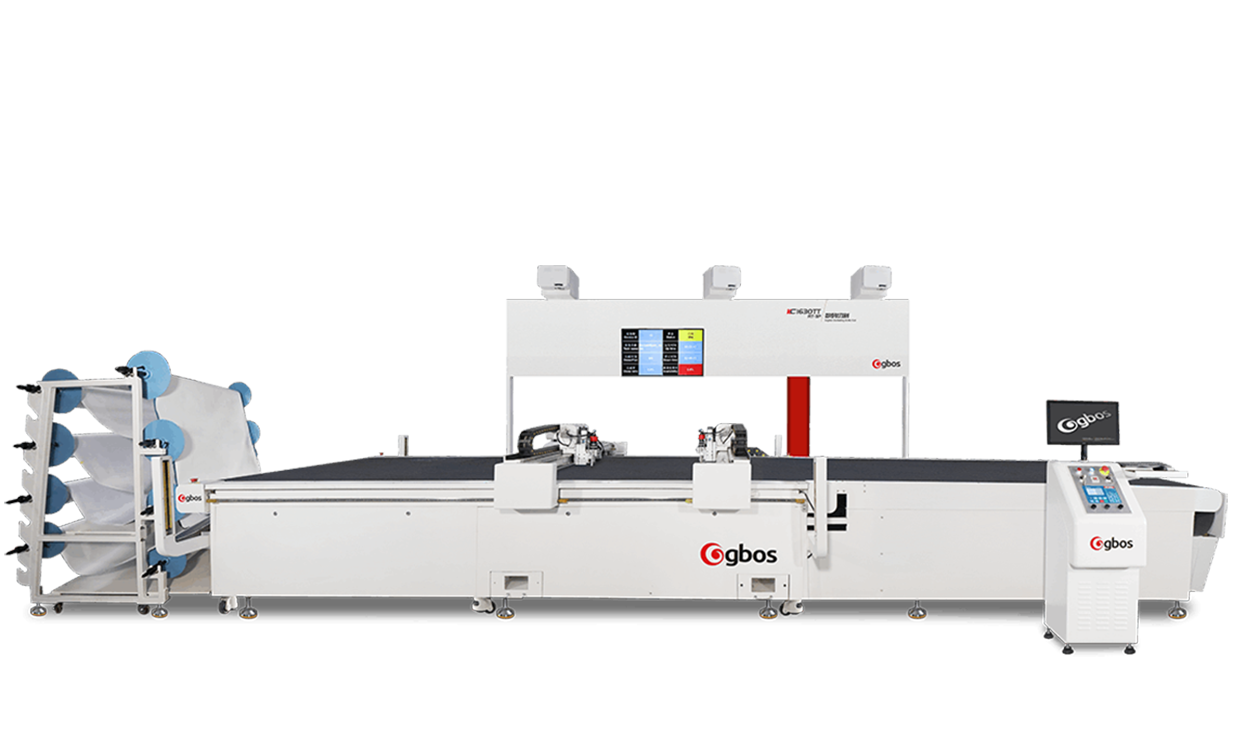

FULL MATERIAL LEATHER DIGITAL CUTTING

Model: KC1630TT-RT-3P

Specification Parameter

The right cutter for every segment

Perfection in all details

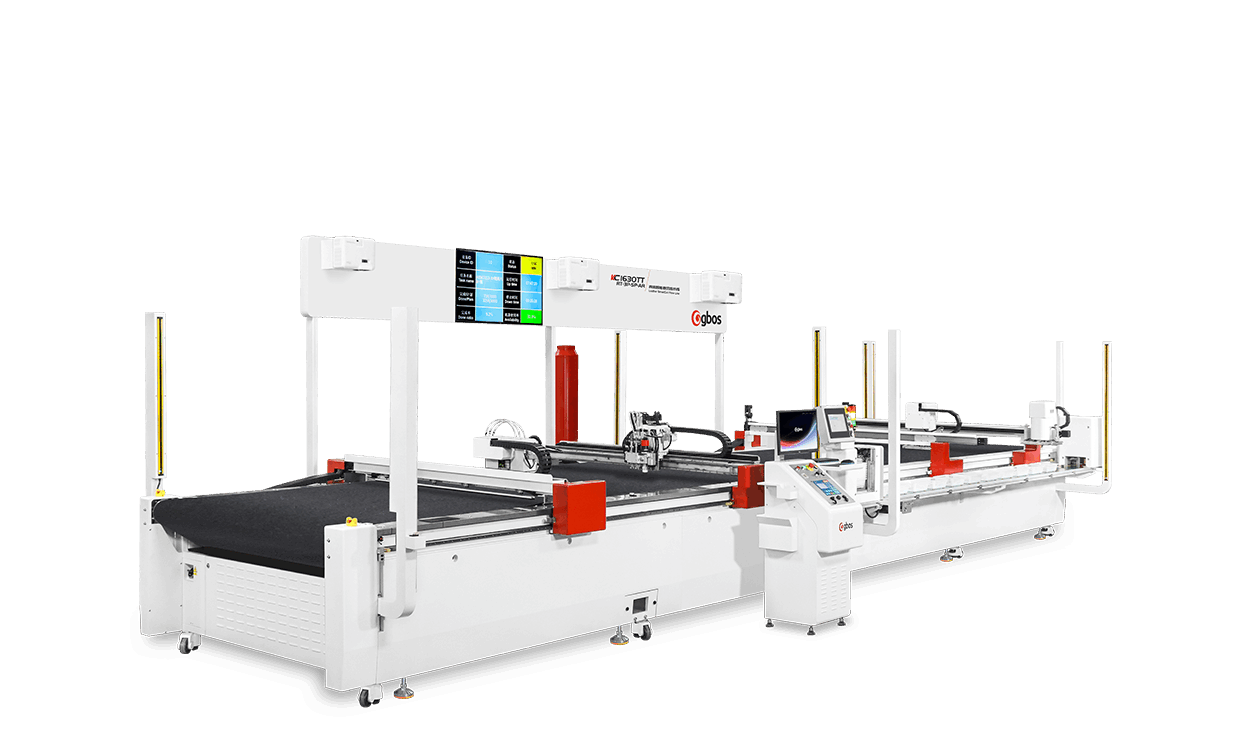

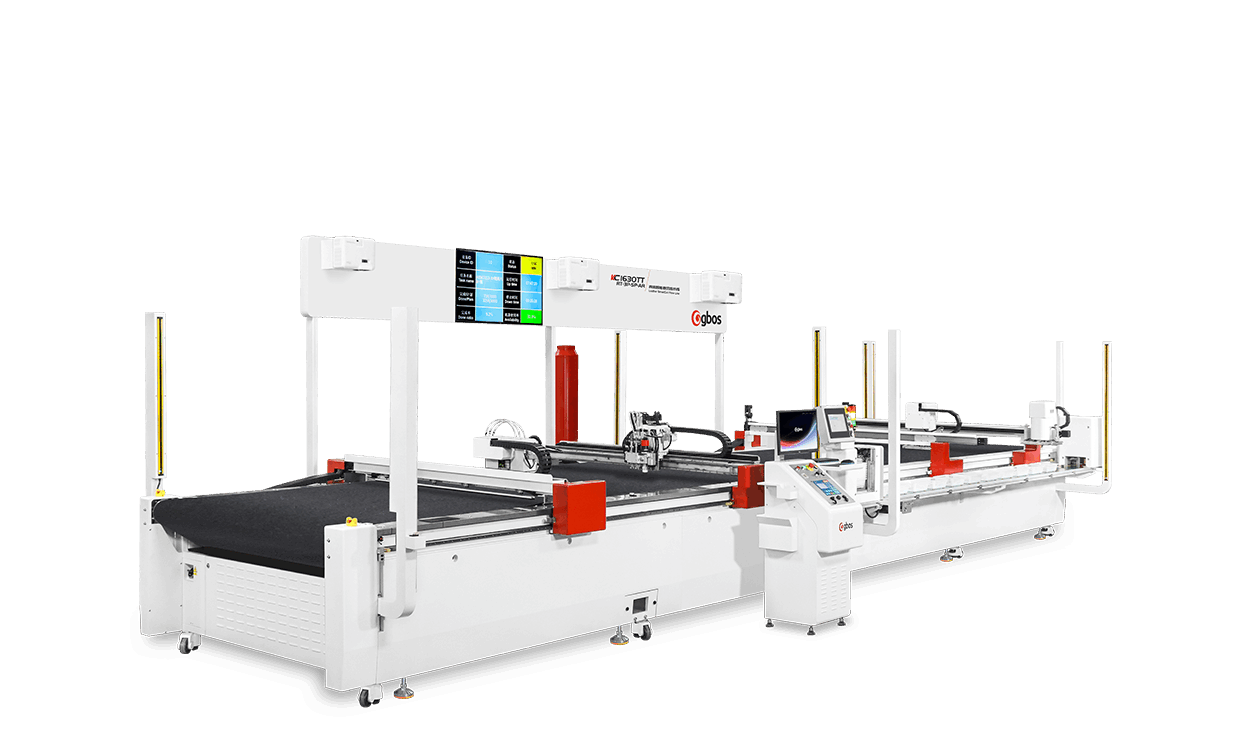

Dual-head asynchronous cutting system

Equipped with an integrated cutter head, it can simultaneously perform cutting and punching. With dual heads operating asynchronously, it effectively increases production capacity.

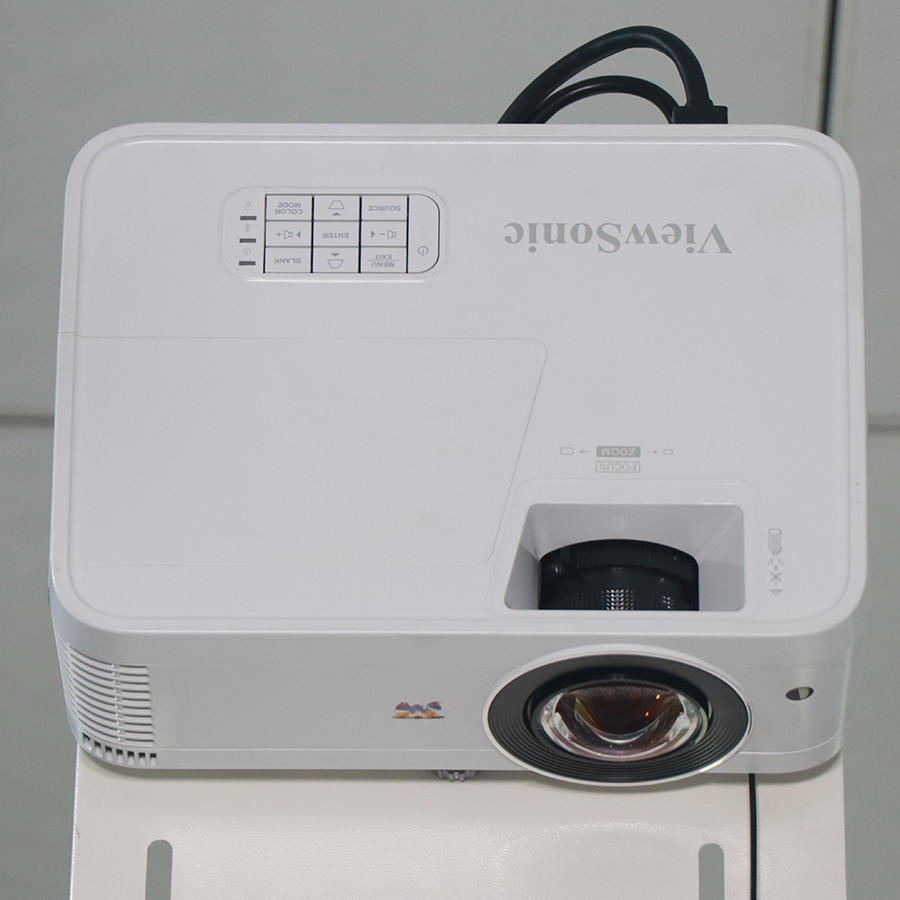

Projector positioning system

Nesting effect real-time preview, convenient and fast; the insert knife position can be adjusted as needed.

Intelligent nesting system(Optional)

Equipped with a smart material-saving nesting system, capable of automatic nesting for unlimited lengths, improving material utilization.

SP Ink Cartridge Marking Unit (optional)

The ink cartridge unit prints sequential identification marks onto the material before cutting, enabling more organized and efficient collection after cutting.

AR Automatic Material Pickup Unit(Optional)

Robotic arms automatically pick up the cut panels and place them into collection frames, enabling automatic pair matching and eliminating the need for secondary manual sorting.

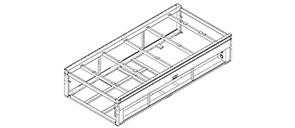

Integrated casting frame

Casting and natural weathering 24 months in advance, stable structure, high corrosion resistance, high precision cutting, lifespan of 20 years.

Independent control system

Stable and reliable, built-in microcomputer and external PC control system, double guarantee.

Cast T-plate

The core components of the knife holder are made through integral casting, reducing the use of screw fastening. This design ensures high-strength usage without the risk of decreased precision.

Double beam four-wheel drive

The machine features two X-axes and is equipped with four drive systems, enhancing operational efficiency and stability.

Integrated molding X-axis beam

The gantry structure is made through integral casting, making it stronger and more durable than aluminum structures. This results in a longer machine lifespan and higher cutting accuracy.

Partitioned vacuum system

Through zoned suction, it ensures the flatness of the material and reduces the likelihood of misalignment.

RT Receiving table with scrap collection device

Receiving table and scrap collection device, cutting and receiving on the same machine; hidden removable collection box, more convenient and easier to operate, durable.

IoT Bridge

Achieve control over the entire smart workshop through digitalization, break down data silos, and improve production efficiency and equipment maintenance.

Modules & Tools

Material Application

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts