GBOS Stands Out at 2025 GISMA: Gaining Widespread Praise from Numerous Users

On May 28, the 2025 Guangdong International Intelligent Shoemaking Machinery Exhibition (GISMA), alongside the Guangdong Footwear Materials & Leather Supply Chain Exhibition and Fashion Trendy Shoes Exhibition, officially opened at Guangzhou's Poly World Trade Center in Pazhou.

Themed "Harnessing the Power of Innovation to Reshape Footwear Manufacturing," this year's event brought together nearly 300 leading companies across shoemaking machinery, materials, and design. Spanning 20,000 square meters, the exhibition served as a global hub for cutting-edge technologies and industry trends.

GBOS Takes Center Stage with Breakthrough Solutions

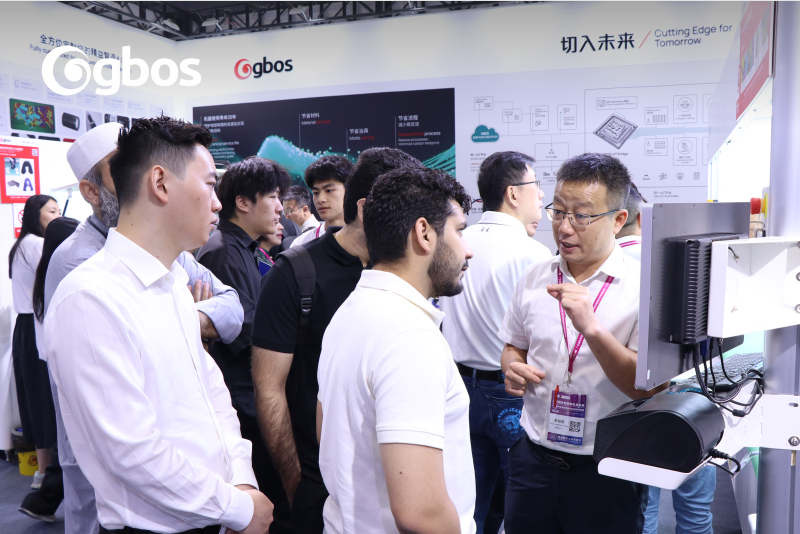

As a pivotal exhibitor at the event, GBOS emerged as the center of attention, captivating the audience with its cutting - edge next - generation intelligent manufacturing solutions. Among this impressive array of innovations, the "AI Digital Cutting Center" shone brightly as a formidable catalyst, propelling the footwear industry towards high - quality development.

This groundbreaking innovation proved to be a major draw, attracting a substantial influx of visitors. They flocked to the GBOS booth, eager to engage in profound and meaningful exchanges, eager to learn more about how this technology could revolutionize their own operations.

AI Intelligent Leather Nesting System (ITS3 - 3012)

This system is integrated with the state - of - the - art GBOS deep - learning AI large model. It offers remarkable advantages of becoming increasingly intelligent, user - friendly, and material - efficient with prolonged use. The leather utilization rate consistently stays above 85%.

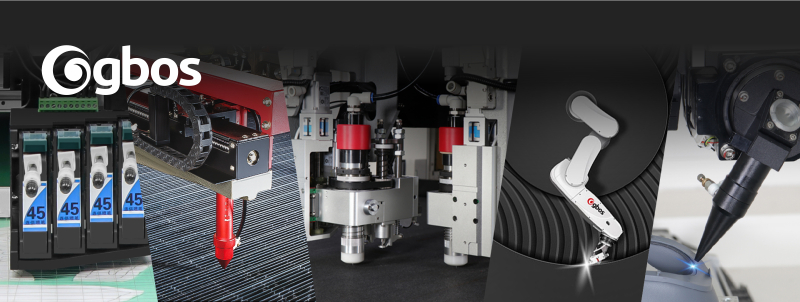

SOKC Super Intelligent Cutting System (VC9 - 1670T/N - 4SCCD)

Not every oscillating knife deserves the name "SOKC". This solution is capable of precisely identifying and executing positioning cutting of monochromatic mesh fabrics in colors like white and black, as well as cutting or secondary trimming of materials featuring patterns or logos.

Gantry - Type Intelligent Oscillating Knife Cutting Machine (VC9 - 1665T)

This solution was officially unveiled in Jinjiang in April 2025. The machine boasts a high - end configuration at a budget - friendly price. It is equipped with a brand - new "waste suction device", ensuring that the cleanliness of the cutting area exceeds 90%. Guided by the philosophy of "unleashing performance and evolving value", it is well - suited for multi - layer cutting of regular materials.

MULTI - FUNCTIONAL HIGH - RISE PRECISION DIGITAL CUTTING BED (H3 - T)

This equipment is primarily designed for cutting shoe - machine linings and insoles, with a cutting thickness capacity of up to 5 - 6CM. It stands as an ideal solution for mass production.

High - Precision Industrial Ink Cartridge Marking Machine (IP - GH1280 - AT - 2SCCD)

This machine provides a wider marking and recognition range along with higher precision. A single ink refill can last for over 10 days of continuous operation, eliminating the need for frequent refills. The ink has strong compatibility, resulting in clear marking lines free from ghosting or breakage. The marking precision error is less than 0.1mm.

Unveiling of New Products to Drive High-Quality Development in the Footwear Industry

On the morning of the first day of the exhibition (May 28, 2025), Mr. Liu Wen, the CEO of GBOS, officially launched this highly groundbreaking new product - the KC1625TT - RT - 2P - ITS3 - SP Leather Intelligent Cutting Production Line. Designed specifically for mass - production scenarios, this product is equipped with GBOS's newly upgraded ITS3 Leather Intelligent Nesting System. As a result, this machine integrates multiple functions into one, including AI - powered intelligent leather nesting, leather coding/marking, dual - head asynchronous cutting, and automatic material collection (optional) or manual material collection.

This new product can significantly enhance users' production capacity and efficiency. Most importantly, there is no need for manual secondary alignment of leather materials when using this machine, further improving both efficiency and precision.

Accelerating Digital Transformation in the Footwear Industry, GBOS Leads the Future with Innovative Technology

In the grand process of footwear industry development, digital transformation has become an unstoppable wave of the times. With its outstanding and cutting-edge technological innovation capabilities, GBOS acts like a fearless pioneer, continuously delivering groundbreaking solutions to the market, infusing the footwear industry with a constant stream of innovative momentum.

GBOS deeply integrates multiple advanced technologies to build a comprehensive, intelligent one-stop solution for shoe manufacturing, including smart cutting and innovative processes. The synergistic effect of these advanced products creates a highly forward-looking and competitive production environment for users, helping them prepare in advance for future challenges and maintain an invincible position in fierce market competition.

As clearly demonstrated by GISMA 2025, the blueprint for the future of footwear manufacturing is already drawn—digitalization and innovation are the core driving forces behind industry development. GBOS is putting this vision into practice through continuous technological innovation and product upgrades, lighting the way for the digital transformation of the footwear industry and leading it toward a more glorious tomorrow.