DIGITAL CUTTING STRONG WEAPON

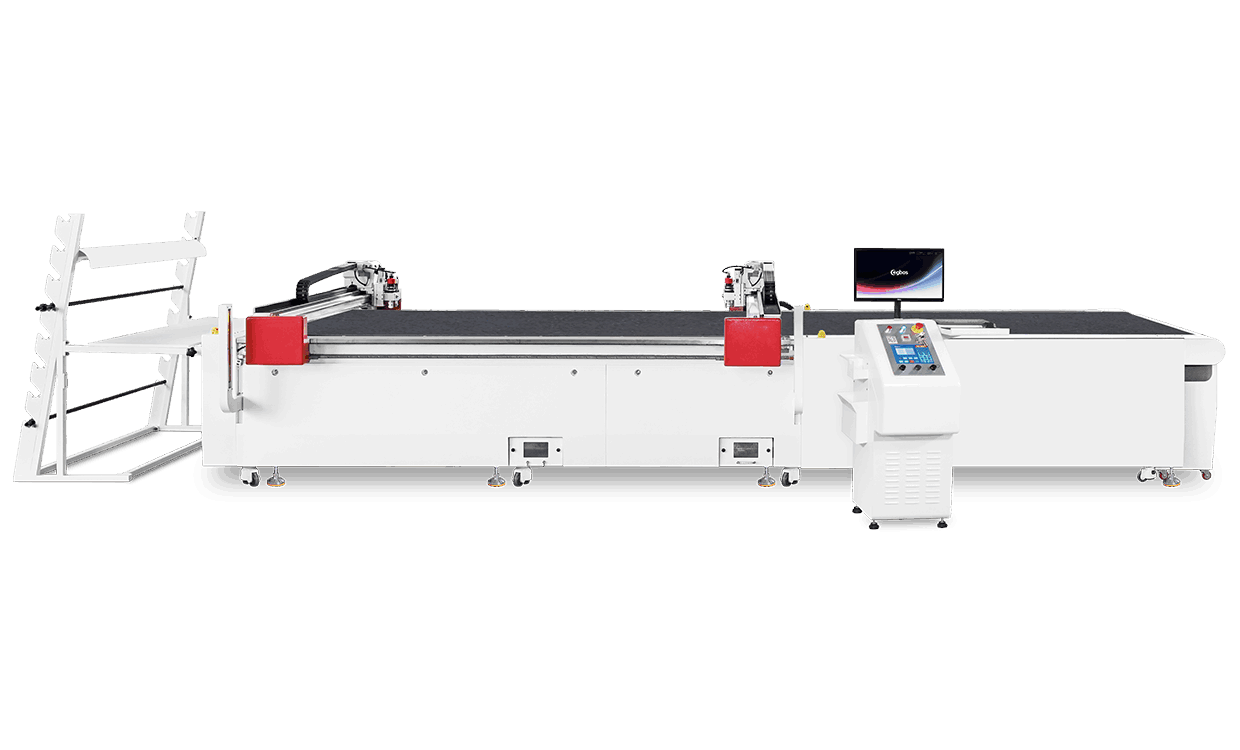

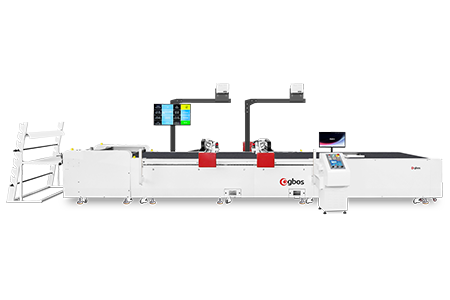

Model: KC1625

Specification Parameter

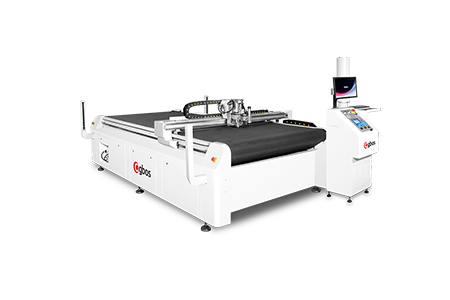

The right cutter for every segment

Perfection in all details

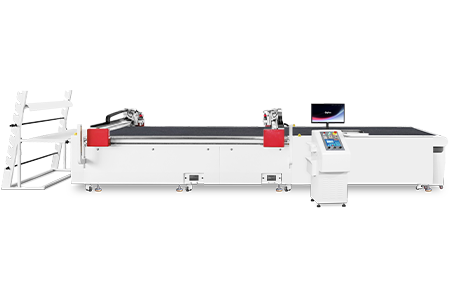

Clamping and feeding system

Real gripping and feeding system, feeding material smoothly and no winkle, multi-scences application; Support cycle feeding and multi-layer feeding.

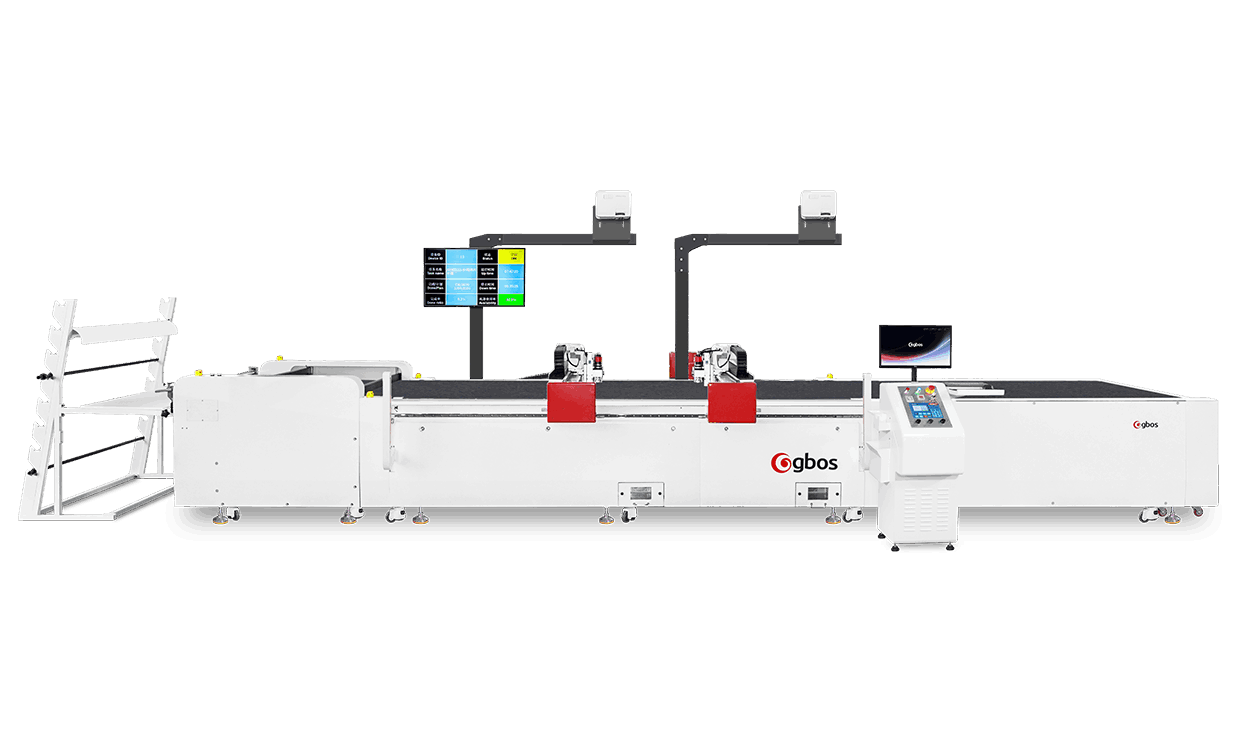

AI visual recognition system(Optional)

Intelligent recognition of various patterned, LOGO materials, and support for secondary cutting processes.

Projection preview positioning

Nesting effect projection preview positioning, convenient and efficient"

CCD VisionScan(Optional)

Supports feature point positioning cutting, multi-point positioning cutting, feature contour extraction cutting, and intelligent recognition cutting.

ITS2/ITS3 AI Leather Nesting System

Leather utilization rate is over 85%, equipped with the latest GBOS AI large model, becoming smarter and more material-saving with use.

ITS Regular Material Nesting System

Supports multi-part graphics for intelligent nesting to save material; the same graphic can be arranged in a positive and negative cross-over pattern for extra-long continuous nesting, improving material utilization.

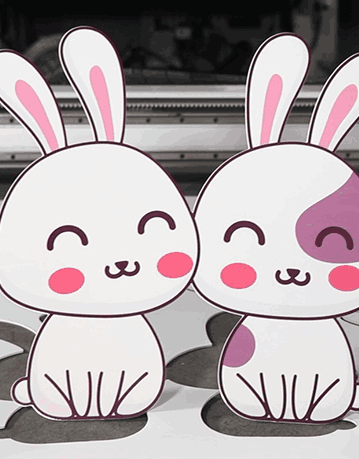

Color sensor(Optional)

Suit for sign & graphic, packing & printing industry, like the materials: sticker, packing, KT board, self adhesive paper, cardboard.—— Feature point locating and cutting; Positioning multi patterns cutting in a fast speed.

Equipped with collecting table

More convenient to collect materials

IoT Bridge

Achieve control over the entire smart workshop through digitalization, break down data silos, and improve production efficiency and equipment maintenance.

Modules & Tools

Material Application

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts