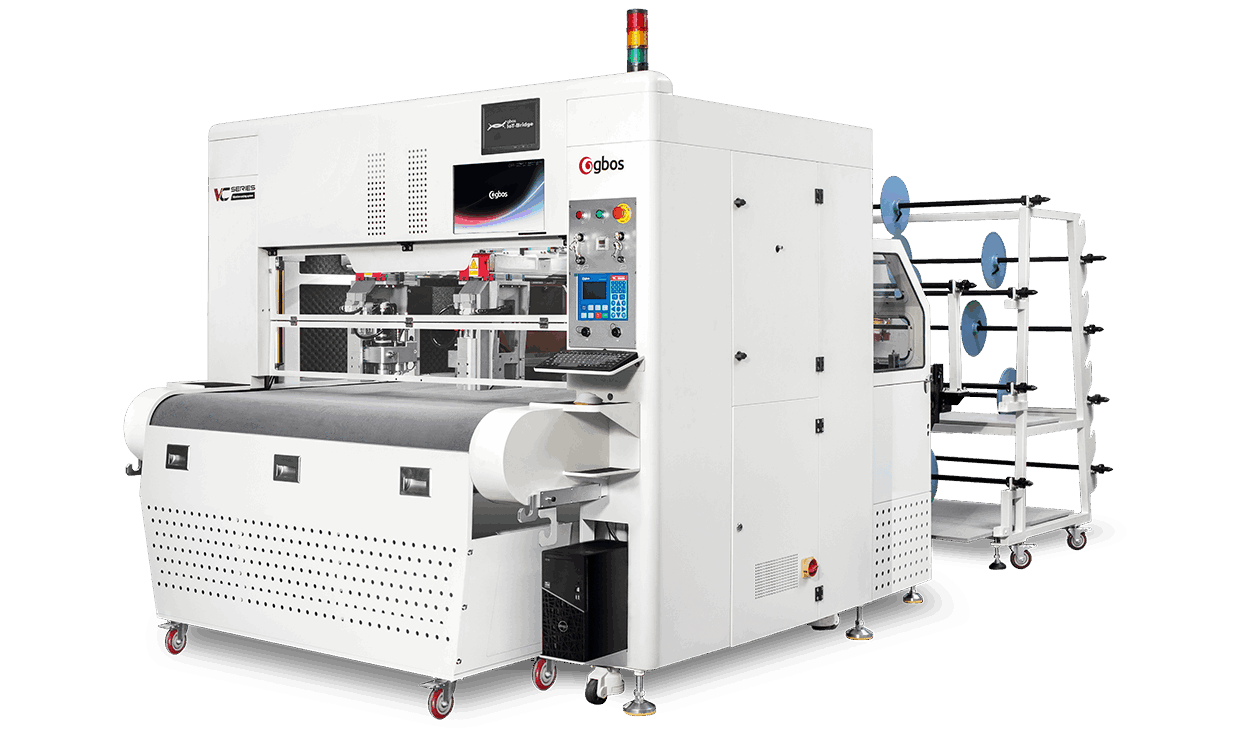

MULTI-FUNCTION AI CAMERA POSITIONING OSCILLATING KNIFE CUTTING MACHINE

Model:VC9-1670T/N

Specifications Description

The right cutter for every segment

Expand More+

Perfection in all details

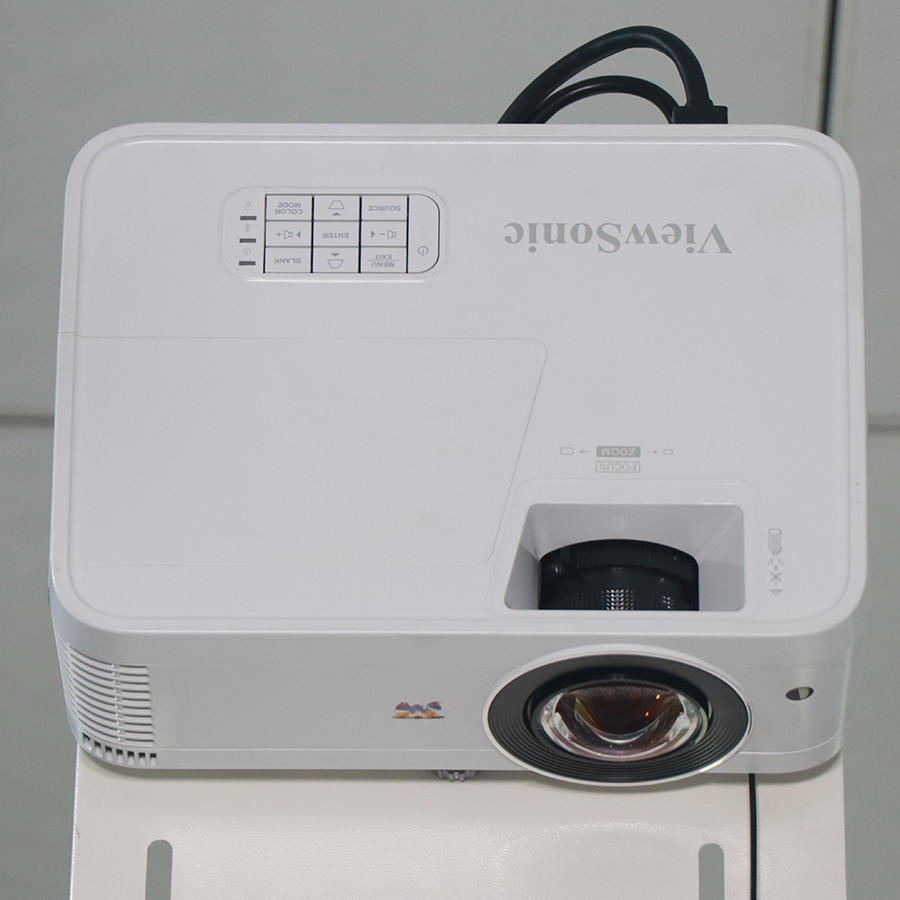

Dual projector positioning

Instant preview of nesting effects — convenient, fast.

SCCD AI VisionScan module optional

Optional SCCD, 4SCCD can be configured to achieve "knife modification process, digital printed material cutting, same color series mesh fabric recognition cutting, and patterned, LOGO material cutting."

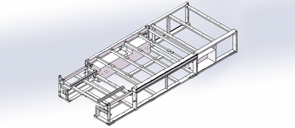

Integrated casting frame

Casting and natural weathering 24 months in advance, stable structure, high corrosion resistance, high precision cutting, lifespan of 20 years.

Dual-head async system

Suitable for various shoe uppers cutting, Perfect dual head async motion control systems, greatly improve processing speed and quality.

Smart nesting system

This feature is more reasonable compared with the normal patterns arranging. It is easier to operate and save materials. It is capable of arranging odd number of patterns, cutting leftover materials and divided cutting of large patterns (unlimited feeding length).

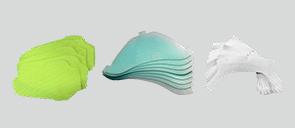

Multi-layer cutting

Multi-layer digital cutting, suitable for the mid sole, TPU/PU, gasket, leather, rubber, toe puff, mesh upper, shoe sublimation fabric, insole, gloves/caps and other flexible fabric, etc. Greatly improve productivity and efficiency.

IoT Bridge

Achieve control over the entire smart workshop through digitalization, break down data silos, and improve production efficiency and equipment maintenance.

Automatic feeding, gripping feed system

Genuine intergrated feeding system not stripping. Multi-materials auto-feeding including knitted fabric, cloth, leather, foam (capable of multi-layer feeding). The software can automatically measure the feeding length according to nesting, Matching one sheet perfectly with another, saving materials. Gripfeeding to ensure materials flat and stable.

Partitioned vacuum system

Partitioned vacuum system is suitable for any kind of materials. It can effectively fix the material, ensure cutting quality. While also having energy saving design.

Pneumatic knife, electric knife (optional)

Standard pneumatic, Catering to various cutting needs. Multi-option are available including 5 types of knife, 1 marking pen, 2 types of punching heads. Pneumatic knife, electric knife (optional) high speed separate punching.

TUV & SGS safety level of double certification

Low noise design, sound decibel ≤ 85 decibels; High standard safety protection design, Effectively protects operational safety.

Modules & Tools

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts