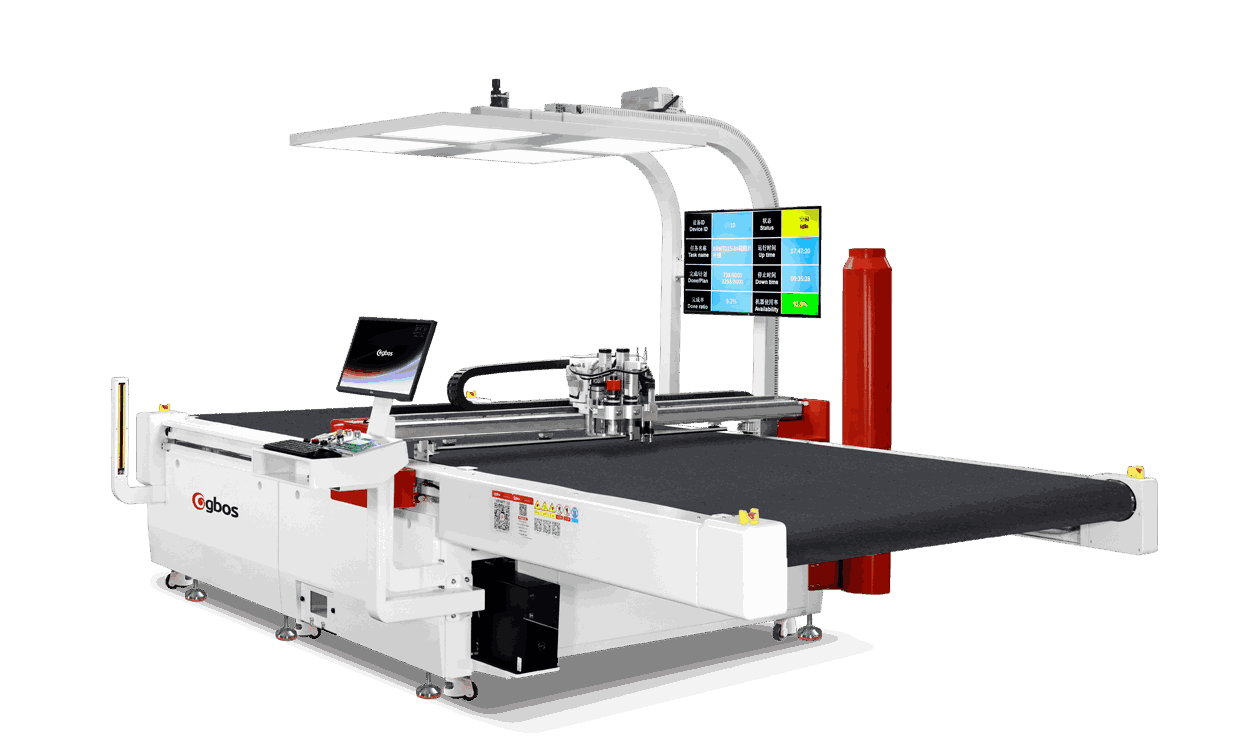

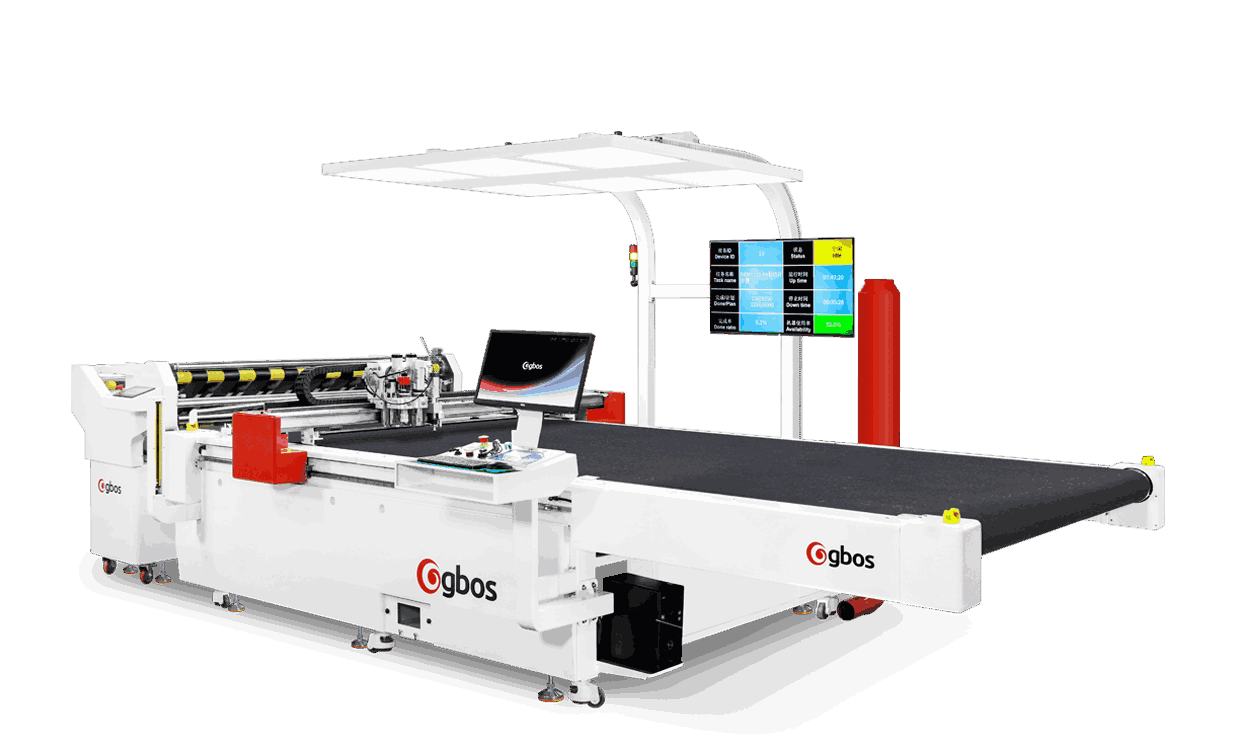

MULTIFUNCTIONAL SINGLE-PLY DIGITAL CUTTING MACHINE

Model: VC9-1820SSCCD

Specification Paramete

- MODEL

- Description

- Processing Area(mm)

- Max cutting speed

- Acceleration

- Gross Power

- Weight

- Measurement (L×W×H)

- System/ compatible Format

The right cutter for every segment

Perfection in all details

AI SCCD VisionScan system

Feature point locating and cutting/Multipoint locating and cutting/Contour extraction and cutting/Intelligent recognition and cutting.

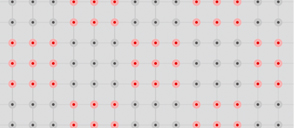

AI SSCCD VisionScan system

Equipped with AI SSCCD, achieving high-end stripes, dots, horizontal textiles with higher precision.

Integrated knife holder design

Integrates multiple devices such as "round knife, pointed knife, round punch, V-shaped punch, and pen", which can be selected according to needs.

Dual-head async system

Suitable for various shoe uppers cutting, Perfect dual head async motion control systems, greatly improve processing speed and quality.

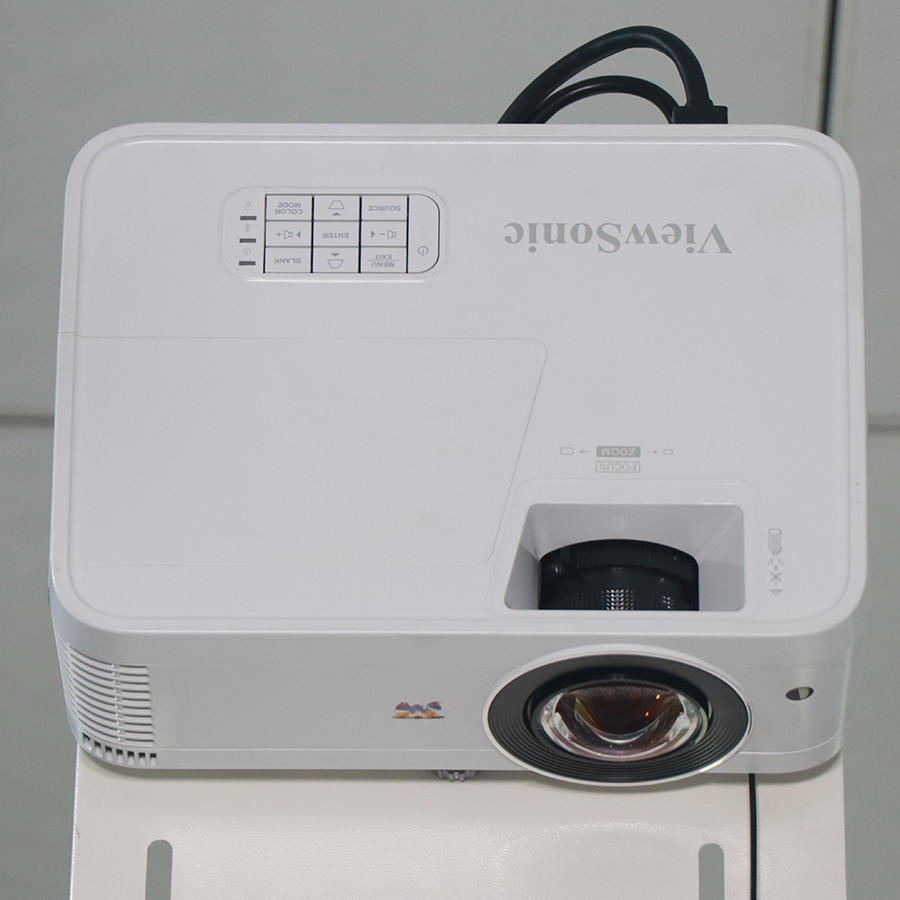

Projector positioning system

Clearly project the nesting effect onto the material, allowing real-time viewing of the nesting effect and cutting status.

ITS regular material nesting system (optional)

Optimize material nesting to improve material utilization.

High-end customization & automatic solutions for apparel

It's applied to plaid, striped apparel, shirts, suits and other materials that need to be cut in pairs of plaids and stripes.

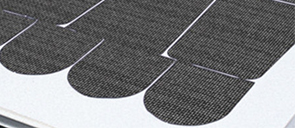

Achieve the perfect cutting effect

Achieve smooth and seamless cutting edges, enabling the creation of high-quality custom uniforms with single-ply cutting.

Intelligent fabric feeding device (optional)

Experience smoothly feeding, wrinkle-free production.

Partitioned vacuum adsorption

Ensuring Effective Material Fixation and Superior Cutting Quality. Experience unparalleled accuracy and reliability in every cut.

IoT Bridge

Achieve control over the entire smart workshop through digitalization, break down data silos, and improve production efficiency and equipment maintenance.

Modules & Tools

Material Application

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts