H3-T: A Rising Star in the Flourishing Footwear Industry

In the footwear industry, cutting multi - layer foam and hard EVA materials is a critical step, yet many factories face significant challenges.

Pain Points in Footwear Factories

Unstable Material Feeding

Traditional cutting machines often use felt for material feeding. Felt wears out fast, causing inconsistent feeding. Foam or EVA layers may shift or bunch up during cutting, leading to misalignments. Workers have to stop the machine frequently to adjust, slowing production and increasing labor costs.

Poor Cutting Precision & High Waste

Cutting thick foam and composite layers precisely is tough with traditional methods. Cuts are often rough and uneven, wasting a lot of material. High - cost EVA foam is especially affected, and inaccurate cuts limit the variety of products that can be made.

Low Productivity & Long Lead Times

Slow cutting speeds and the need for manual interventions mean low productivity. Factories struggle to meet large - scale, fast - turnaround orders. Long production times delay deliveries and tie up resources, preventing business expansion.

The H3 - T Solution

We've developed the H3 - T Multi - functional High - layer Precision Digital Cutting Machine to tackle these issues.

Stable Feeding System

The H3 - T replaces felt with durable "brush bricks" and has a high - suction feeding system. Brush bricks grip materials gently and consistently, while high suction keeps them in place. This ensures a smooth, automated feeding process, reducing downtime.

High - Precision Cutting

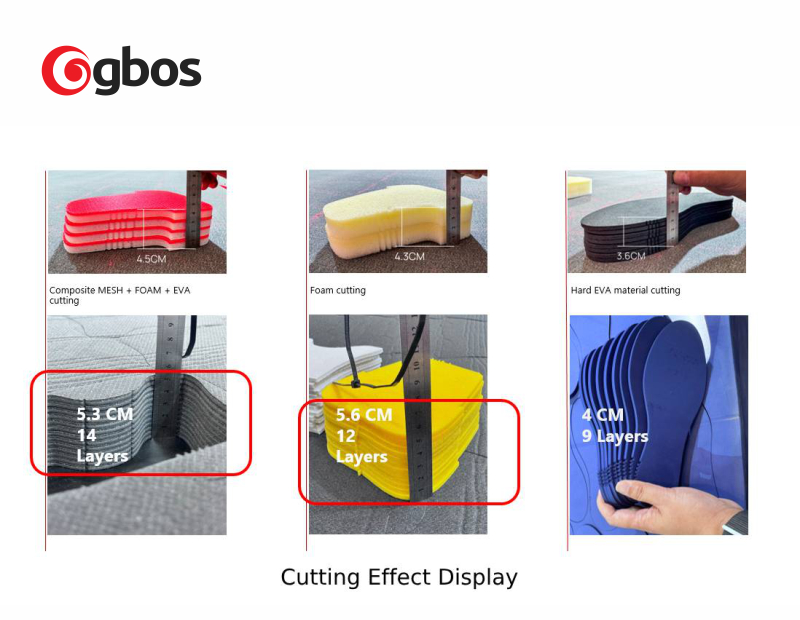

With a cutting height of up to 5-6 cm (material-dependent), it can easily handle various types of cutting requirements. Whether it's the top layer or the bottom layer of the material, when taken out and compared, the shape and size remain highly consistent, with extremely low error.

High Productivity

The H3 - T can cut 7,000 to 15,000 pieces per hour. This high speed improves efficiency, allowing factories to meet large orders quickly. Automated processes reduce the need for manual labor, cutting costs and increasing output.

The H3 - T is a game - changer for the footwear industry. It solves traditional cutting problems, improving productivity, quality, and cost - effectiveness.

As the industry evolves, adopting innovative technologies is key. The H3 - T offers a chance to capture new growth opportunities and increase market share.

Don't hesitate. Contact us now to learn more and schedule a demo. Take the first step towards a brighter future in footwear production with the H3 - T!

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts