Digital Cutting Center, Open and "Same Frequency".

Currently, with the integration of digital technology into traditional industries, new technologies represented by big data, cloud computing and artificial intelligence accelerate the transformation and upgrading of traditional manufacturing industries. And promote the realization of personalized production and on-demand production, various industries are being redefined in the wave of digitalization.

At the same time, the relevant policies introduced for manufacturing enterprises, promoting the transformation and upgrading of the direction of travel, the wave of digital transformation of manufacturing has arrived.

In the current situation where industries are constantly being redefined in the wave of digitalization, and under the increasingly urgent trend of digital transformation of manufacturing enterprises, the transformation and upgrading for smart manufacturing and digital factory has prompted enterprises to make relevant initiatives.

With 18 years of experience in customer applications and research and development, GBOOS also enters the forum, focusing on the problems faced by the cutting end of flexible materials, helping companies build "Digital Cutting Center", in order to promoting the data to empower traditional manufacturing. Below, we summarize a few points to empower enterprises to build digital cutting center.

01 What is a "Digital Cutting Center"?

GBOS Digital Cutting Center is an one-stop solution that combines automation and digital cutting intelligent equipment based on IoT Bridge.

It connects your IT systems to the cutting room, ensuring highly efficient planning, cutting and optimization processes. On this IoT platform, you can find data (find information on products, materials, orders, energy efficiency, performance, etc.), connections (across systems) and applications. Maximize productivity, data sharing and minimal manual intervention through digital management.

02 Five Advantages of "Digital Cutting Center"

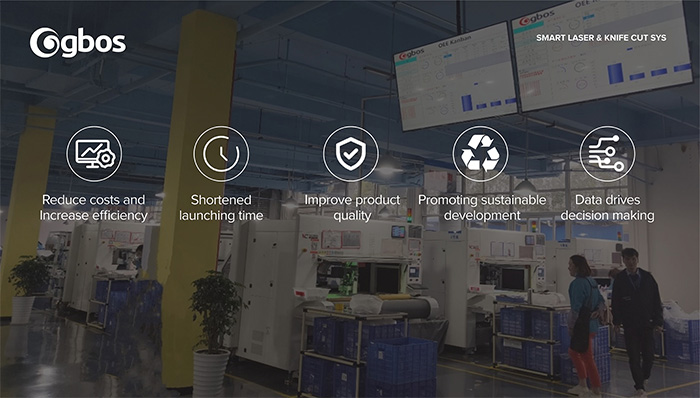

- Cost Reduction and Increased Efficiency: Digitalization enables the production area to function more efficiency, which means that more costs can be avoided due to long downtimes.

- Reducing Time to Market: The pace of business has become faster and faster, and customers will continue to expect new products to come to market. Digital transformation efforts can help shorten time-to-market in many ways: 1. First, by shortening the manufacturing cycle through a mold-free production method; 2. Second, By enabling integrated cutting, line marking and punching operations, reducing the process flow and leading to shorter production cycles.

- Improve the Quality of Products: digitally-driven cutting method, AI-driven visual recognition to extract contours to make the finished products more finer and finer.

- Driving Sustainability: For the manufacturing industry, digital transformation is an effective way to empower companies to meet their "carbon neutrality goals" and "ESG sustainability goals". Through the transformation, the manufacturing industry can reduce and monitor their carbon emissions and achieve refined "carbon management".

- Data-driven Driving Decisions: More completeness and accurate data allows relevant departments to understand manufacturing, gain better analytical insights from the data, and make improvement decisions accordingly.

03 The implementation plan of "Digital Cutting Center"

With the continuous investment and R&D, as well as the accumulation of 18 years of market experience, GBOS has been developing rapidly in digital one-stop cutting solutions, and has achieved remarkable results in the application and implementation end of footwear, automotive interior, upholstery and other industries.

And What is a digital one-stop intelligent cutting solution? That is, the IoT Bridge as a carrier, which covers:

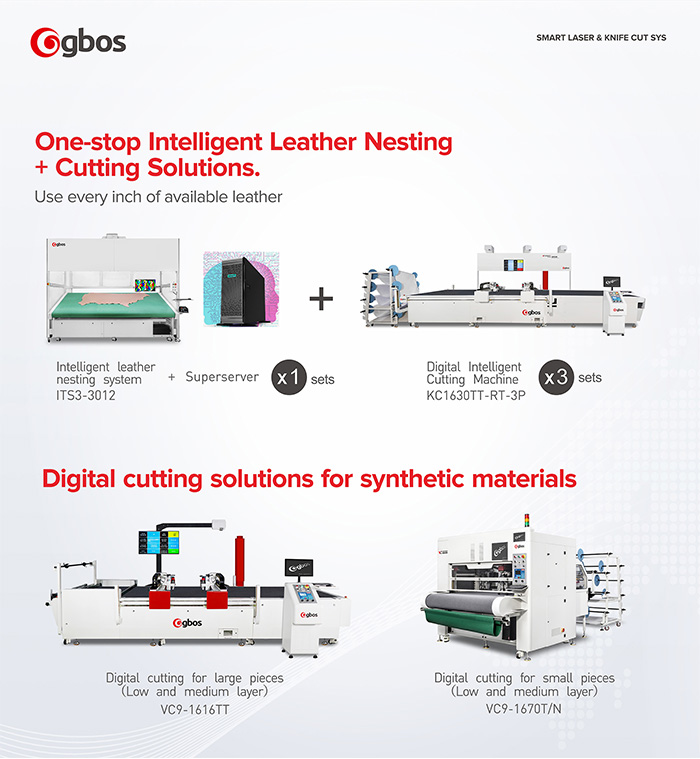

- Leather Nesting and Cutting Solutions: ITS3-3012 leather intelligent nesting system + KC1630TT-RT-3P digital cutting equipment.

- Synthetic material cutting solutions: VC9-1616TT Digital cutting for large pieces(Low and medium layer) + VC9-1670T/N Digital cutting for small pieces(Low and medium layer)

- Small volume order solution: VC9-960 small intelligent cutting equipment. The most important thing is to help enterprises to transform and upgrade, to reduce costs and increase efficiency!

In the process of GBOS helping enterprises to build "digital cutting center", more and more practices and cases prove that the importance of digital transformation to the sustainable development of enterprises is clear.

On the way to empower the digital transformation of the cutting field, we don't just imagine a "Digital Cutting Center", we want to turn the imagination of the digital cutting center into reality!

Professional Digital Cutting Solutions

Smart Layout Planning | Sample Testing | ROI Analysis | Technical Support | Training | Custom Solutions | Parts